Finishing materials for pools. Facing the pool with foil and tiles

A very important component is how your future pool will look. In many respects this is determined by your personal preferences, as well as the talents of designers.

To date, we are ready to offer a lot of options for finishing the pool from tiles and mosaics, to unique solutions in the form of custom-made stretch marks, curbs, mosaic panels. A rich assortment of finishing materials, also presented in our store, gives an opportunity to offer our customers any solutions from simple to exclusive.

In our projects, we use only the most reliable and time-proven materials with a number of properties, such as: wear resistance, resistance to low temperatures, water resistance, etc.

Examples of our works on the lining of the pool basin with mosaic

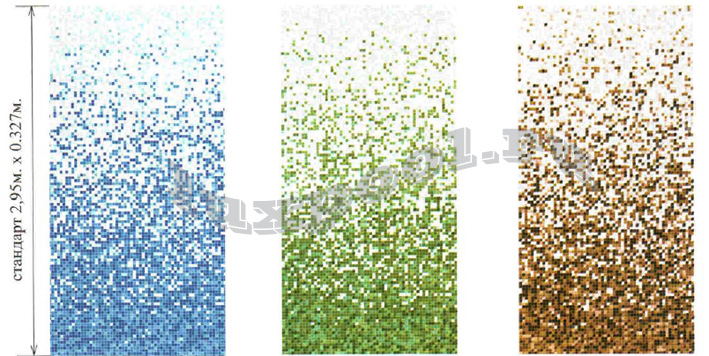

Stretching in the pool

One of the most interesting and effective solutions is the stretching in the pool bowl. Stretching is a mixture of mosaic, with the transition from darker tones to light, so the so-called "depth effect" appears in the bowl. Stretching we produce in our studio, on factory matrices, directly under the size of the bowl.

Decoration / mosaic basin tiling

Since the mosaic has small dimensions (from 10x10 mm.), It is the most actual material for finishing bowls of basins and hammams, especially irregular shapes, with rounded corners, sides, a Jacuzzi zone and so on. No tile or film can beautifully bypass all corners or vice versa rounding.

The small size of the mosaic element allows you to give non-standard, smooth lines to the pool shapes. And their colors are able to satisfy the wishes of the most demanding customer. Installers of the company Therma have extensive experience in laying mosaic in the pool, we give a guarantee for all our work.

Facing / finishing the pool with tiles

Facing tiles - a more economical version of the basin lining. Such material as tile lusha is most suitable for pools of direct shape (rectangular, square). In some cases, we combine mosaics and tiles to decorate the pool.

Facing pools - a short educational program for those who want to beautifully design the surface of the pool.

We will do all the work qualitatively, quickly and correctly!

One of the main elements in the design of any pool is a respectable look of finishing its inner bowl. Make right choice will help you with several suggested options.

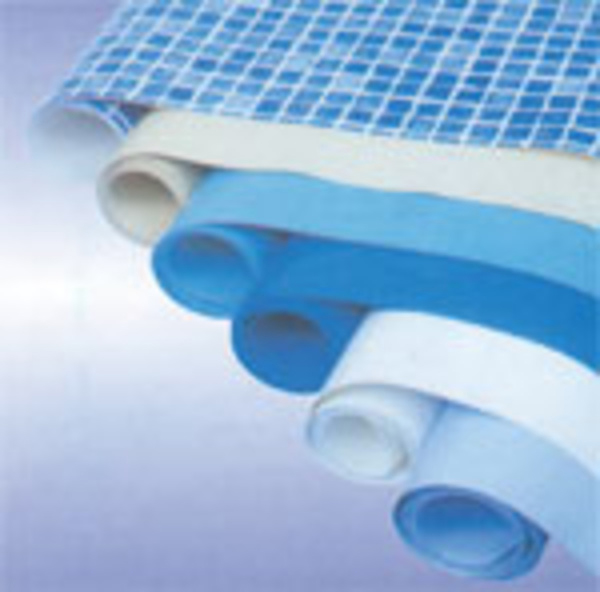

The very first and simplest way to finish the swimming pool of any pool is to finish using PVC film. This proposed project is the fastest in terms of time and is economical enough financially. Moreover, you will save on the arrangement of the waterproofing system, because in terms of its physical properties, such a film does not by itself pass water and moisture, only a special material has to be glued to the film beforehand.

The very first and simplest way to finish the swimming pool of any pool is to finish using PVC film. This proposed project is the fastest in terms of time and is economical enough financially. Moreover, you will save on the arrangement of the waterproofing system, because in terms of its physical properties, such a film does not by itself pass water and moisture, only a special material has to be glued to the film beforehand.

Today, in the market for building materials, manufacturers are exhibiting various models of films with a wide variety of patterns and colors. The technological process for lining the pool with a film is very simple. Select the finishing film you need to cut into pieces and weld at the seams, using a thermal hair dryer. To the side of the pool finishing material is attached using a special profile. The main caveat is that the trim beads do not have on their working surface elements of large gravel and reinforcement.

In the manufacture of work with finishing film, you must also focus on the function of proper pre-cutting it. It is necessary to take into account such specific properties as the ability of the film to stretch during the filling of the pool with water. Therefore, entrust the stage of work on the cutting of PVC film to a specialist or a specific profiling organization.

However, not everything is so simple and easy. Such a relatively cheap type of finish has, of course, its drawbacks:

- A short time of operation of the pool, finished in this version. It averaged six seven years.- The repair period of the finishing film is not more than twelve months. PVC, which has served more than a year, can not be repaired.

Its front surface simply "creeps" away from the heat flux of the hair dryer.

- In the event of a possible occurrence of a situation where there are defects in the system of external waterproofing,

and groundwater enters the basin from the external environment, these waters create so-called

bubbles between the concrete bowl and the film. There is also visibility of the joints that are formed when attaching sheets of film.

- If your choice in the option of finishing suddenly fell on a PVC film, when a swimming pool of a skimmer type is installed,

then do not count on the bright uniform color of your swimming bowl over a long period of use.

Under the influence of ultraviolet rays, the chemical composition of water, which is disinfected by special

components, the color scale of the pool lining over the water surface will be markedly different from the color

gamma part of the pool, most of the time occupied by water.

- When facing a pool of pools with an overflow tray, you will need extra material costs

To equip the tray, which gives the effect of overflow.

- Under the influence of minus cold temperatures, the PVC film undergoes a fracture process.

PVC FILM

Glass Mosaic

Mosaic is a kind of aesthetic art, color background, picture or image made of various ceramic tiles, colored pebbles, smalt, glass and so on. It could be found even among the peoples of ancient Egypt. It operates with a different color scheme, it is defi- nished in configuration and geometric dimensions. It differs by zero level of moisture absorption and is not at all afraid of negative air temperatures.

Mosaic is a kind of aesthetic art, color background, picture or image made of various ceramic tiles, colored pebbles, smalt, glass and so on. It could be found even among the peoples of ancient Egypt. It operates with a different color scheme, it is defi- nished in configuration and geometric dimensions. It differs by zero level of moisture absorption and is not at all afraid of negative air temperatures.

Installation work on laying such aesthetic art reproduce on the face of the walls and the bottom of the pool, performing truly fascinating color structures. And if you resort to the help of mosaic masters, then the general aesthetic range of the basin will be enriched with mono-diverse panels in the form of marine flora and fauna. Such designer nuances will make your pool exclusive and unforgettable for a long time.

Installation work on laying such aesthetic art reproduce on the face of the walls and the bottom of the pool, performing truly fascinating color structures. And if you resort to the help of mosaic masters, then the general aesthetic range of the basin will be enriched with mono-diverse panels in the form of marine flora and fauna. Such designer nuances will make your pool exclusive and unforgettable for a long time.

Very aesthetically and attractively it looks like a properly made interior based on a mosaic of various colors and sizes, the very room where the bowl is for swimming. Having resorted to the help of highly qualified designers and modern computer programs, you will be able to see in advance the picture of the future basin in the measurement of 3G, that is, from any point, from any angle or from any height. This additional service does not require large additional costs.

Very aesthetically and attractively it looks like a properly made interior based on a mosaic of various colors and sizes, the very room where the bowl is for swimming. Having resorted to the help of highly qualified designers and modern computer programs, you will be able to see in advance the picture of the future basin in the measurement of 3G, that is, from any point, from any angle or from any height. This additional service does not require large additional costs.

The sketch of the future painting is first drawn by the artist. Then it is processed on a computer. Colored illustrations chosen by the artist are subject to the correction process in accordance with the available common background and the color structure of the existing mosaic. In simpler versions, the maziku is spread on paper or mesh with rectangles of specified sizes 20 * 20 or 10 * 10mm, which in the general construction form a 327 * 327 mm matrix.

The sketch of the future painting is first drawn by the artist. Then it is processed on a computer. Colored illustrations chosen by the artist are subject to the correction process in accordance with the available common background and the color structure of the existing mosaic. In simpler versions, the maziku is spread on paper or mesh with rectangles of specified sizes 20 * 20 or 10 * 10mm, which in the general construction form a 327 * 327 mm matrix.

On the finished surface of the swimming bowl, first apply a layer of waterproofing. After it has dried, use a comb spatula to lay glue for the mosaic, which looks like a paste. And only after these operations begin to lay mosaic. The seams between the elements of the mosaic are wiped with a special glue composition for swimming pools, in common folk called grout. It includes latex, and if desired, epoxy resins.

MOSAIC MIXTURES

STRETCHES

BURDURES

![]()

PANNO

Ceramic tile

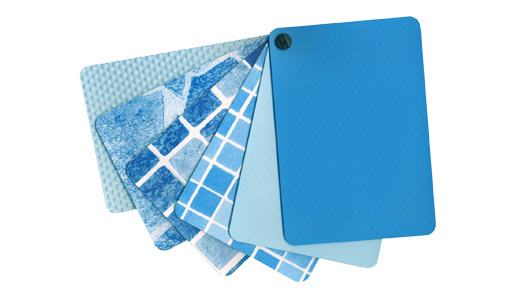

The next option is no less popular for the lining of the swimming pool bowl is the use of ceramic tiles. Its main catalog contains colors: navy blue, blue, green and white.

The next option is no less popular for the lining of the swimming pool bowl is the use of ceramic tiles. Its main catalog contains colors: navy blue, blue, green and white.

Combining and combining these basic colors with other varieties of tiles:

- Semi-matte smooth;- Semi-matte relief;

- rough anti-slip

You can create a design version of the finish in more saturated colors.

The dimensions of the ceramic tiles produced are 5 * 5, 10 * 10, 15 * 15, 17 * 17, 20 * 10, 20 * 20 centimeters. It has a fairly low water-absorbing function and increased convenience in terms of labor for laying works. Therefore, this option is used, much more often for finishing pools. And if you still decorate the side of the swimming bowl with a handrail tile, you will get a very refined version.

CERAMIC TILE

![]()

HANDICATOR

Create a style of your home

Nowadays any sane person has a desire to make his home comfortable and cozy. Water and everything associated with it, occupy an important place in human life. That's why you can talk about great popularity and great prestige, if the house has its own pool.

Think about it? What can be more beautiful than enjoying in the warm, blue waters of your home pool or the whole family to gather in the evening by the water, or to drift a couple of hundred meters in the morning instead of morning exercises.

Think about it? What can be more beautiful than enjoying in the warm, blue waters of your home pool or the whole family to gather in the evening by the water, or to drift a couple of hundred meters in the morning instead of morning exercises.

To fulfill all your ideas regarding your new swimming pool, where after an exhausting working day, you can relax, you need to make the right choice and think about the shape, appearance and materials for finishing your pool.

Today, the market of facing materials for finishing the pool is very expanded and varied. Everything depends only on the customer, his tastes and desires. And even the most demanding demands will find their answer in the form of a positive decision.

The right and the most accurate choice will be those who stop their views on the material that has earned respect and respect worldwide - ceramic tiles. This long-known type of finish differs at all times with long-lasting reliability and a high level of quality.

Facing the tile can also replace the option with a glass mosaic, which will become the most expressive face of your place to relax.

Having found your solution with a facing structure, you will still need to choose the constituent elements of the decor. These include: tile borders and an attractive mosaic panel. They decorate the bottom of the pool, and the side walls. Having made such an exclusive image, you will receive at home a masterpiece of a work of art that will talk about the style of your house, your thoughts and feelings.

If you dream of making your home special, unforgettable for all time, in which there is everything necessary for a normal life, then make sure that you have a place to relax in your home as a swimming pool.

Facing the bowl of the concrete basin is performed at the final stage of construction works. The tile or mosaic that will be used in the process of finishing the bowl, determines the beauty of the design. Visitors may not appreciate the technical characteristics - an effective ventilation system or a complex pump device, but they will notice and remember the beautiful pool lining.

Modern technologies and materials make it possible to turn the pool basin into a real work of art. Qualified specialists of the company "POSEIDONSTROY" will help to realize any design ideas.

Which material should I choose?

In the process of selecting the material for facing, it is important to consider that it must have the following properties:

- resistance to water,

- long service life,

- attractive view,

- resistance to the emergence and development of mold and microorganisms,

- chemical inertness to aggressive substances that can be used for water purification.

Traditionally, the following materials are used for facing the pool, which meet the listed requirements:

- ceramic or glass tiles,

- a natural stone,

- mosaic,

- PVC film.

In addition, in the zone of descent into the water and at the outlet from the pool, it is best to lay the material with an inverse surface - this minimizes the likelihood of injury.

Advantages and disadvantages of materials

When choosing a material, you should also take into account the intensity of use and location of the pool.

- Synthetic film is well suited for finishing swimming pools in a private home. This is affordable material, the cladding can be done without much difficulty. The advantage of this option is that this coating creates additional waterproofing. However, the service life of such a coating is relatively short-term - with chlorine disinfection about 5 years, with chlorine disinfection about 10 years, and temperature changes can lead to cracks and damage.

- Facing with tiles is a traditional solution for both outdoor pools and bowls located inside the building. Due to the variety of products offered, you can easily choose the right option. The operating life of this material is 15-20 years.

- By choosing a pool mosaic tiling, you can create a unique and colorful decorative finish: intricate patterns or whole panels that look very impressive. You can choose any story at your discretion - fairy-tale heroes, bewitching scenery or intricate ornament. However, the very method of creating a mosaic pattern is long and painstaking, so this option is one of the most expensive. In this case, the service life of the coating is the same as that of the tile.

- Also, for finishing the walls and bottom of the concrete pool, natural stone can be used - most often it is granite. The main disadvantage of the material is high cost. The stone is well suited for the decoration of outdoor pools, as it tolerates climatic influences and this coating is almost eternal.

Why should you contact the company "POSEIDONSTROY"?

The company LLC "POSEIDONSTROY" renders services in the lining of pools ceramic tiles, mosaic and other materials.

- We carry out work of any complexity.

- Finishing is done by qualified specialists.

- Designers of our company, at your request, will prepare an individual project of facing.

- The employees of "POSEIDONSTROY" will select the optimal material for your project according to the cost and performance characteristics.

Cost of pool finishing

|

Facing, material type |

Price per square meter. m of the pool finish |

Contents Types of internal and external waterproofing How to choose the right waterproofing material Polymer materials Waterproofing pools with membranes Waterproofing on the basis of cement Waterproofing the pool with liquid glass and rubber PVC film Additional materials High-quality waterproofing of the pool is necessary for the successful functioning of ...

The construction of a pool of polypropylene will allow you to surrender the owner of a modern artificial pond that meets all the requirements of the standards set for home pools. Use as a finishing and waterproofing polypropylene endows erected from it ...

Times when the home pool was a luxury that could afford a unit, long gone. Today, the construction of a home pool is quite an affordable pleasure for many Russians. Modern materials and technologies, qualified specialists, ...

Pool assemblies are very popular and deservedly sought after, as they save not only time, but also significant financial resources, which are always associated with the construction of stationary pools. Construction of prefabricated pools ...

The construction of swimming pools must be carried out according to clearly defined sanitary standards. Implementation of hygienic requirements for the construction of swimming pools will allow to meet all the conditions necessary to achieve a healing effect when swimming, and -

The construction of swimming pools is a multi-stage exercise, which must be carried out in accordance with well-defined rules and regulations. There are standards and regulations that the pool must meet, especially if it's about ...

The main feature of the pools is 25 meters is that they are used for all sorts of sporting events. In such pools you can hold: competitions in sports and synchronized swimming; competitions in diving; competitions on ...

Indoor pools are very popular among Russians, as, unfortunately, the climate of our country, even in the warmest regions, does not allow year-round use of natural reservoirs and outdoor pools. Construction of a closed ...

The construction of an overflow pool will allow you to become the owner of a real swimming miracle. Pools of overflow type look very impressive, especially since modern technologies and materials allow realizing any design decisions.

Composite pools are a special kind of basins, fundamentally different from concrete structures. The material of the bowl of such a basin is a multiple layering of different polymers and resins on a matrix mold, hence their name is ...

Stationary pools are monolithic concrete structures, which are distinguished by their strength and high performance characteristics. The use for the construction of such concrete basins necessitates the mandatory conduct of all stages of construction and installation work, including: digging ...

Street pools or, as they are still called, summer cottages are built everywhere, even in a climate of severe climate. Despite the imperfect climatic conditions in such regions, modern materials, equipment and ...

Monolithic construction of pools from the company AstraPool - is the erection of reliable hydraulic structures of concrete. Compared to composite and frame structures, monolithic basins are characterized by higher strength and durability. Among...

Construction of concrete pools is a priority activity carried out by AstraPool. Many years of experience, equipping with modern equipment and tools, our own production facilities and competent personnel allow us to guarantee our customers ...

The pool is a great place for a comfortable and relaxed holiday, which should be comfortable and aesthetically attractive, meeting all safety requirements. The company "AstraPool" specializes in the construction of modern swimming pools in Moscow ...

Then you will need to finish it. Decoration of the pool basin is not such a simple task, as the inner surface of the bowl is constantly exposed to the destructive effects of water and additional hydraulic loading acts on it. Therefore it is very important to choose suitable types of materials and use certain technologies of work.

Any casting of the concrete bowl will not be performed perfectly smoothly, so the first stage of finishing works is leveling the walls.

Decoration of the pool basin must be carried out according to a certain technology of plastering. In this case, apply plaster on the grid or glue application method of plaster.

Method I. Plaster on a grid

If you use conventional sand-cement mixtures for finishing the pool, they do not provide reliable adhesion. Therefore, first fix the steel plaster mesh, and then apply plaster. There are such drawbacks. In the process of using the pool, sooner or later, the penetration of water, which penetrates through the layer of plaster to the metal mesh, will cause corrosion of the metal. In this case, the plaster may begin to fall off together with the tile. Undoubtedly, anti-corrosion coating is applied on the mesh, modern plasters are of very good quality, but still such an outcome is quite possible.

How can I solve this problem?

- To improve adhesion, make the concrete surface of the pool basin a bit rough.

- Use not a steel, but a synthetic or glass plaster mesh.

- Use waterproof plaster mixtures with good adhesion to concrete.

Method II. Adhesive method of applying plaster

Before plastering, the concrete surface is cleaned and treated with special impregnations of deep penetration. Such impregnations have in their composition various polymers: epoxy and acrylic resins, urethanes and others. They create an adhesive layer, to which will be glued the next layer - leveling. The composition of the plaster mixture should include an adhesive polymer.

There are certain requirements for the quality of plastering. When plastering, cracks, depressions and protuberances are not allowed. Small irregularities (up to 1 mm) are allowed in an amount not exceeding two pieces per 4 sq. M. m. Vertical surfaces can have deviations of no more than 1 mm per meter.

Waterproofing of swimming pool

One of the main tasks in the construction of the pool - to ensure its reliable waterproofing. For these purposes, modern and efficient materials are used: cements for hydraulic structures (SC, HYDRO-S, etc.), dry waterproofing mixtures (HYDRO-S, Hydrotex, DISOM, Sopro and others), penetrating waterproofing materials (Penetrat, Stromix, Kalmatron, Sileksol-PM, etc.)

Finishing the bowl of the pool

Finishing of the individual pool is usually done with ceramic or glass tiles, mosaic or film. It is very rare to finish with natural stone, for example, marble. Perform work on the installation of tiles or mosaics can be at an air temperature of 5 ° C, and the film is decorated with a film from 15 ° C.

Swimming pool tiles

For finishing the pool use a tile with an increased water absorption coefficient. International standards regulate this figure to within 0.14%, in domestic stores for sale comes tiles with a water absorption coefficient of up to 1%.

Quality tiles can have grooves on the back for better adhesion, different anti-slip elements. There are many manufacturers of tiles for swimming pools, Italian and German tiles are recognized as the recognized leaders. But you can choose good options from other manufacturers, for example, Portuguese tiles and even domestic ones.

Laying of the tile is made on waterproof glue, and grouting of seams is carried out by waterproof grout. Please note that titanium grout has advantages over epoxy grout in greater resistance to mold and fungi.

To decorate the sides, steps, gutters use shaped elements of the tiles, which are many manufacturers.

Mosaic in the pool finish

The mosaic has excellent aesthetic characteristics, it can easily be laid on complex curved surfaces, making all kinds of panels from it. Glass mosaic has high strength, and its water absorption coefficient is zero. But the price for a mosaic covering is very high, therefore such variant also has not received enough wide distribution. And it's not so much in the cost of the tile itself, as in the laboriousness (and, consequently, in the price) of the finishing works. In the home pools, mosaic is often used as a supplement to the basic finish of the tiles (do, for example, panels or finish the sides).

Foams for pool finishing

The film coating for the pool basin, although inferior to the tile and mosaic in aesthetic, but has a number of its advantages. First of all, they are: saving money and reducing the time for finishing work. In addition, the film will ensure a high hermeticity of the bowl, even if cracks appear on the concrete foundation. The service life of such a finish is quite high, and repair work, if necessary, is easy. To prevent slipping (for example, on the steps), a film with an anti-slip ribbed surface is produced.

When finishing the pool with a film of difficulties with the installation does not arise. The main thing is to carefully lay out the cover. The connection is carried out by the apparatus of thermal welding, the welded joints are sealed with a sealant.